Cooling Tunnels

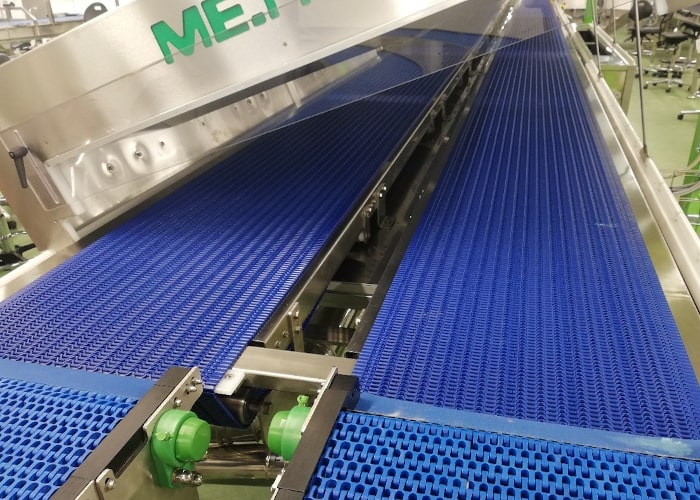

METRA offers a wide range of cooling tunnels technologies: from belt tunnels for baked goods to plastic or metal mesh tunnels for moulds. Belt tunnels for baked goods, plastic or metal mesh tunnels for moulds.

The conveying part is equipped with automatic belt centering system to prevent any skidding. The width of the line can vary from 250 to 2400 mm. The best cooling system is selected according to the specific characteristics of the line: cooling by radiation, convection and conduction, with concurrent or countercurrent airflow to the product movement. The tunnels can be divided into several cooling zones, each with its own air ventilation with independent temperature control. The top covers are perfectly insulated and can be easily lifted and removed; they can also be slid along the tunnel to increase accessibility: thus cleanliness and hygiene are guaranteed at the highest level.

Main features:

- Covers in stainless steel and with high thickness extruded polyurethane insulation easily removable and liftable on both sides. The covers can also side horizontally.

- Double belt centering device.

- Gas temperature expansion 0/+2 °C.

- Product detaching table with its own belt and centering device.

- CE certification.